Contact us

Contact us

Baopack Auto Packaging Machine Co., Ltd.

We provide customers with a wide range of high-quality packaging machines, along with excellent services.

If you would like to leave us a comment please go to Contact Us

Principle of servo electric cylinder: The servo electric cylinder is a modular product that integrates the servo motor and the lead screw. It converts the rotary motion of the servo motor into linear motion. At the same time, the best advantage of the servo motor-precise speed control, precise speed control , Accurate torque control is transformed into-precise speed control, precise position control, precise thrust control; brand new and reliable products that realize high-precision linear motion series.

Servo electric cylinder features: closed-loop servo control, control accuracy up to 0.01mm; precision control of thrust, adding pressure sensors, control accuracy up to 1%; easy to connect with PLC and other control systems to achieve high-precision motion control. Low noise, energy saving, clean, high rigidity, impact resistance, long life, simple operation and maintenance. The servo electric cylinder can be trouble-free in harsh environments, and the protection level can reach IP66. Work for a long time, and realize high intensity, high speed, high precision positioning, smooth movement and low noise. So it can be widely used in paper industry, chemical industry, automobile industry, electronics industry, machinery automation industry, welding industry, etc.

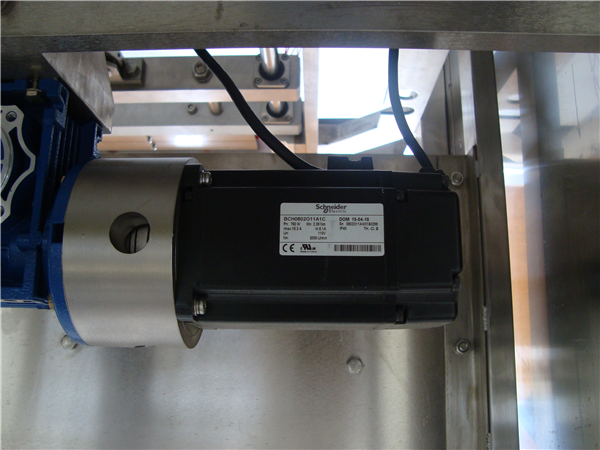

This is the picture of servo motor:

Low-cost maintenance: Servo electric cylinders only need regular grease injection and lubrication when working in complex environments, and there are no wearing parts requiring maintenance and replacement, which will reduce a lot of after-sales service costs compared with hydraulic systems and pneumatic systems.

The servo cylinder takes the standard cylinder as the main body and the electronic cylinder position as the core, and completes the continuous simulation control of the whole process of the cylinder rod extending 0-100% through the given standard analog electrical signal. Generally, servo cylinders can be used in pipeline flow control, air-conditioning duct doors and various pneumatic rectifiers.

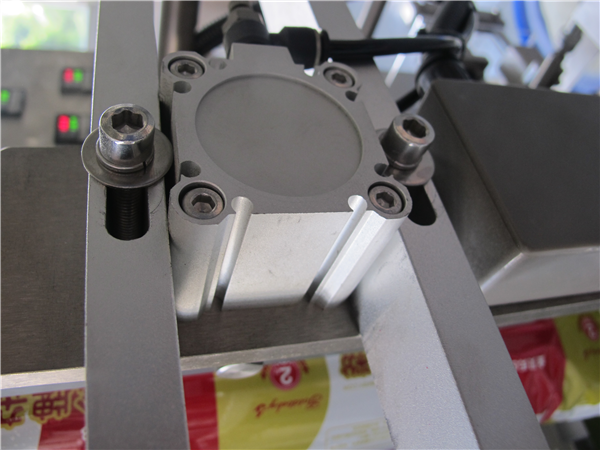

This picture shows the cylinder: